Spirit 600-900C

6-9m

125mm

>170hp

5000 litre

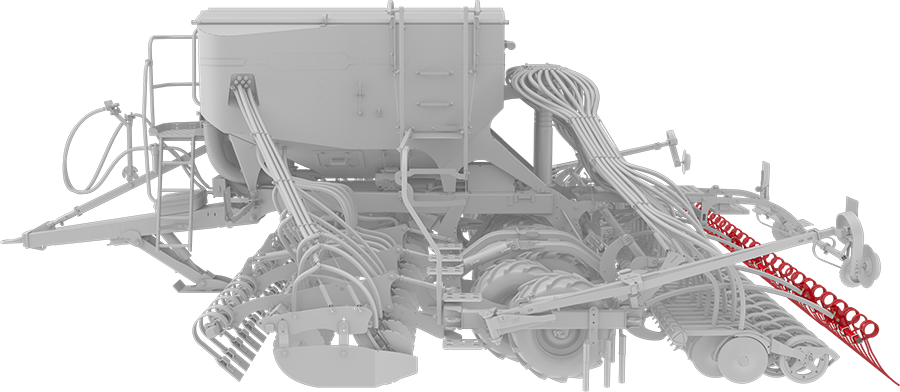

Precision and capacity

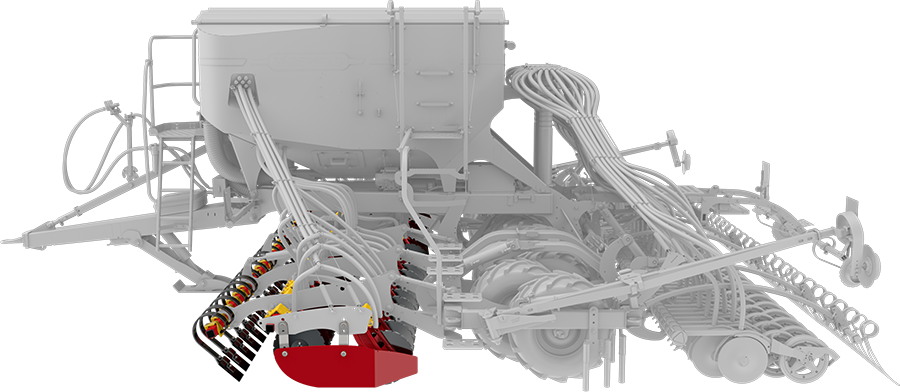

Spirit 600-900C is a pneumatic seed drill for both seed and fertiliser, available in 6, 8 or 9 metre working widths. The 5000 litre hopper with large opening, result in fewer fills. Both the fertiliser and seed metering have impressive capacity. Spirit 600-900C is equipped with innovative solutions that increases the precision and simplifies the operations at the farm.

The pneumatic seed drill Spirit carries out levelling, seedbed preparation, reconsolidation, seeding and pressing in one pass. It is known to provide impressive precision at high working speeds on the field. Thanks to the individual row depth control, Spirit always places the seed at the intended seeding depth. You benefit from an even emergence over the entire field.

Selected features

High capacity seed metering

Spirit 600-900C is equipped with two Fenix II metering systems that provides a constant and reliable seed metering. The strong motor permits high seed rates at high speed.

Due to the high location of the integral fan, the dust intake is minimised, thereby increasing drilling accuracy.

To optimise the air distribution according to the respective seed and fertiliser type, all airflows are adjusted with the integrated AirBalance system.

Fertiliser metering without limits

The fertiliser is metered out via a distributor auger located at the front of the hopper. A hydraulic motor drives the auger and provides limitless fertiliser capacity.

Due to a dividing wall in the hopper, the relation between the seed and fertiliser sections can easily be adjusted. If needed the whole hopper can be used for seed.

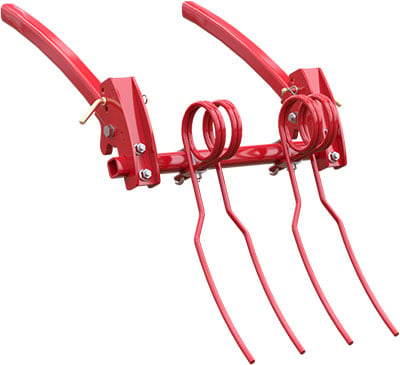

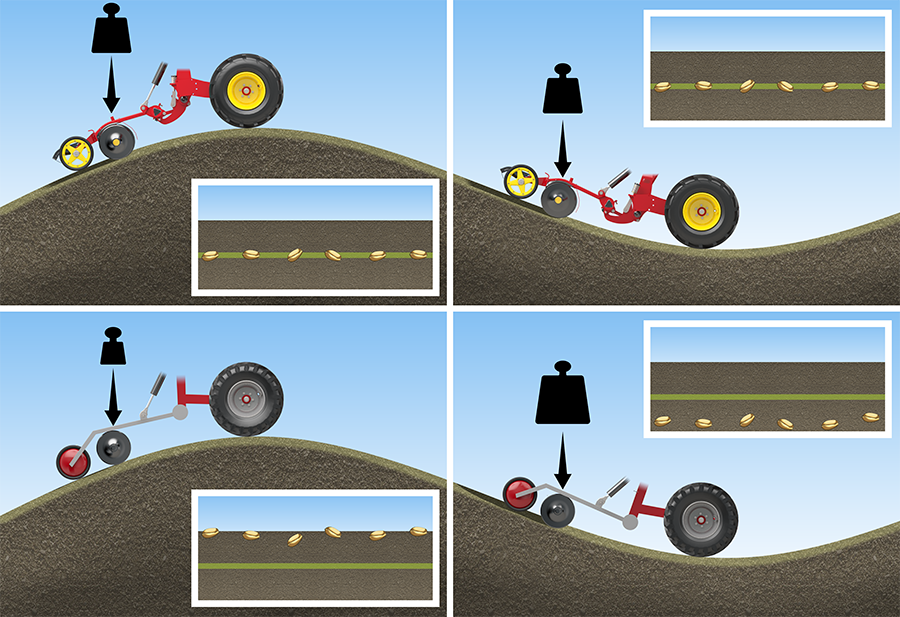

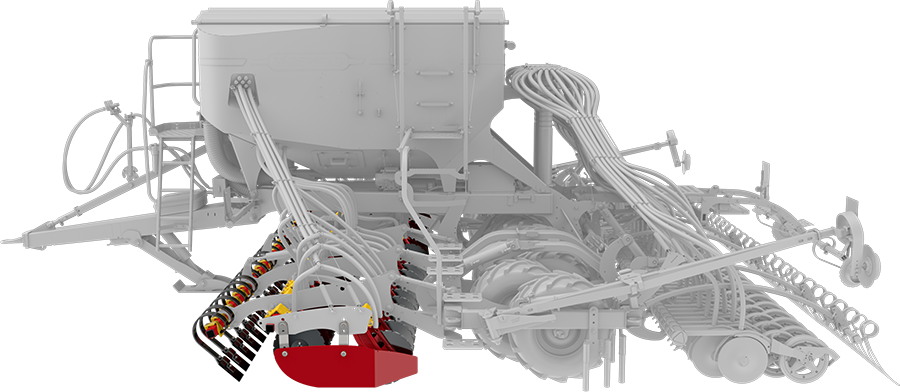

Active coulter and wing pressure

To ensure an even seed depth in hilly terrain and at varying soil types, Spirit 600-900C is equipped with an active seed coulter pressure.

Sensors in the hydraulic system immediately registers if Spirit is located on a crest or a trough. If so, automatic valves directly compensates for an increased or decreased pressure. Thereby the seed coulter pressure is kept at a constant pre-set value, irrespective of which working angle the seed coulters are in, relative to the rest of the machine.

The result is an impressive seed placement and an even emergence over the entire field.

Always the correct distribution

The distributor heads are placed in a high position. This keeps the seed hoses at the perfect angle even in hilly terrain, this ensures a perfect distribution over the entire working width.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Automatic headland management

When lifting or lowering the seed drill at the headland, the automatic sequence control lifts or lowers the working zones one by one. When entering the field the system makes sure the front tool is lowered into the soil before the seed coulters and the following harrow.

By optimising this automatic lifting and lowering sequence, the seeding and fertiliser accuracy is enhanced at the headlands.

This system makes it possible to drill the headland first, without disrupting the result when drilling the rest of the field.

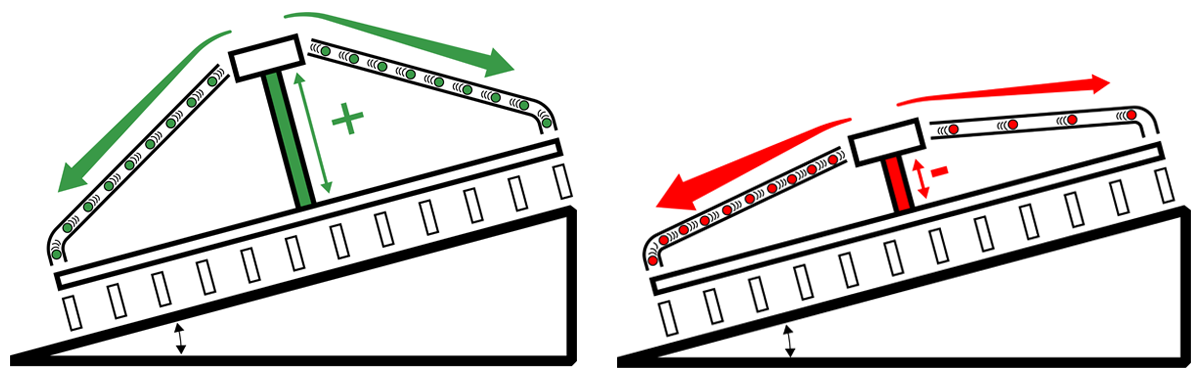

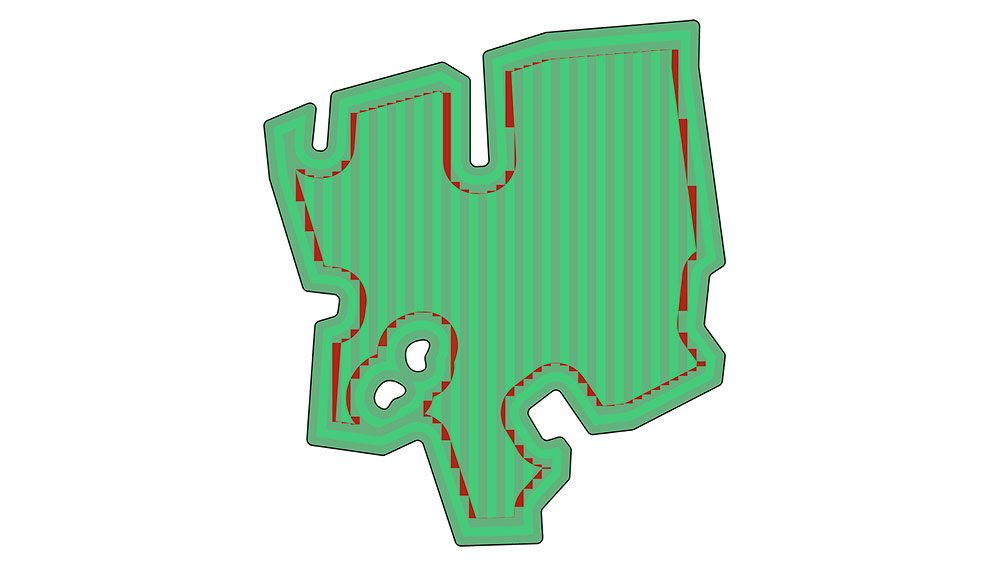

Save money on irregular fields

To offer the ability to optimise the output on the field, Spirit 600-900C is equipped with half machine shut-off for both the seed and fertiliser which helps avoid double drilling and uneven crops.

On irregular fields, this section shut-off offers great opportunities for extra savings.

Farmers who regularly use half machine shut-off appreciate the fact that they can save up to 5 % seed and fertiliser, at the same time allowing the crop the best start possible.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Full control with Väderstad SeedEye

Väderstad SeedEye is a unique system for seed counting and seed monitoring. With SeedEye farmers can easily set the number of seeds per square metre, without the need for calibration. SeedEye ensures excellent seeding results with full control.

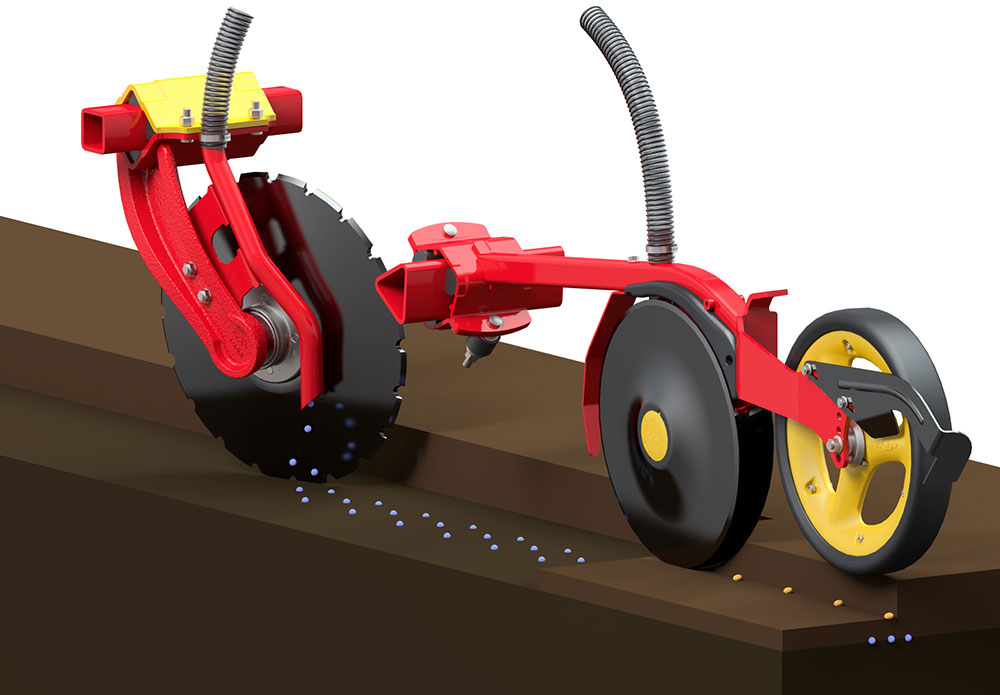

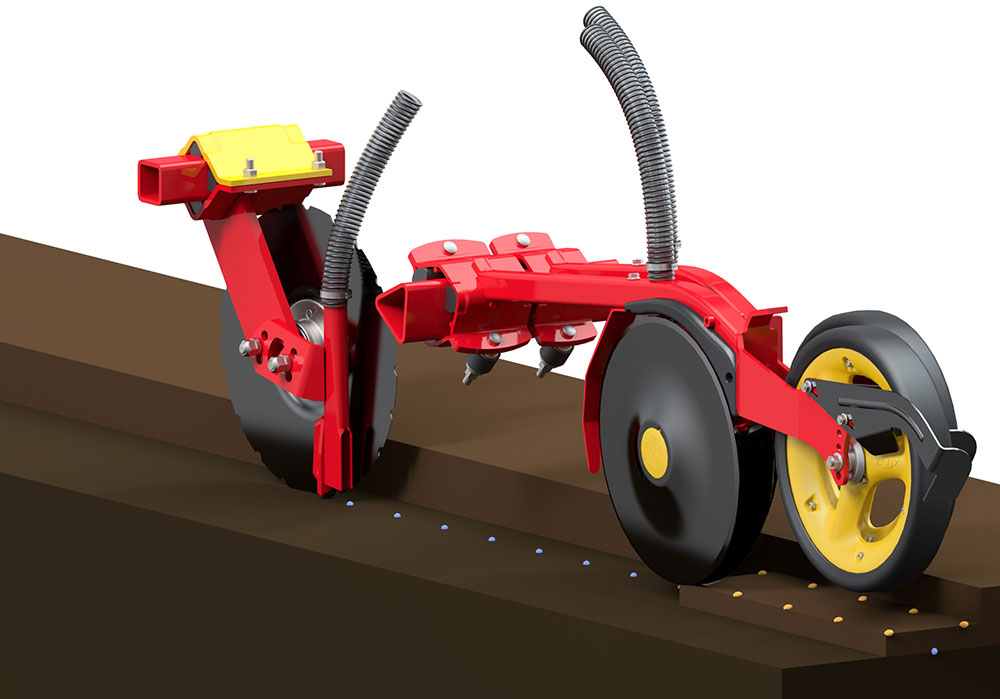

Three techniques to place fertiliser

FIX

The FIX-version have fertiliser coulters mounted in the front tool, eliminating an additional power requirement. The fertiliser is placed in 5cm wide strips at 125mm row spacing, in front of every seed row. The fertiliser depth can be adjusted from the cab according to the soil condition.

Spirit 600-900C FIX is available in 6, 8 and 9 metre working widths. The seed benefits from a fast and effective nutrient uptake.

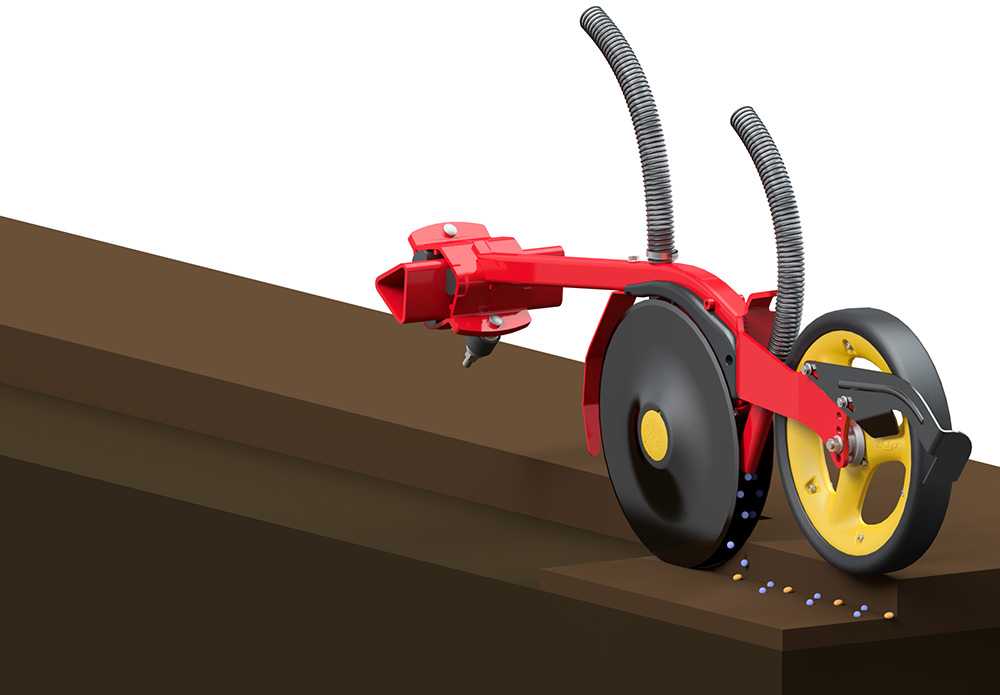

InLine

The InLine-version places a low fertiliser rate in a separate outlet together with the seed in the seed coulter, providing the plant quick nutrient uptake. By separating the seed and fertiliser transport, these two distribution systems do not interfere with each other. This enables separate high accuracy blockage monitoring.

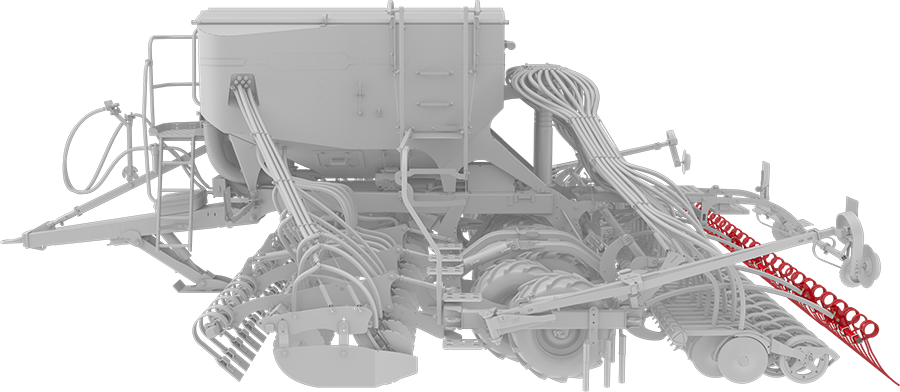

Nordic

The Nordic-version has aggressive disc fertiliser coulters that places fertiliser with a very high coulter pressure between the seed rows at 250mm row spacing. A benefit in conventional tillage spring drilling in dry conditions.

Spirit 600-900C Nordic is available in 6, 8 and 9 metre working widths.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Easy-to-use tramlining

The dynamic tramlining function makes tramlining simpler and more reliable than ever before. The function is easy to setup with the iPad-based control system Väderstad E-Control. When seeding the field, the seed drill automatically shuts off specific rows when needed to match the tyre tracks of the sprayer.

Modern control system

Spirit is equipped with the iPad-based control system Väderstad E-Control.

In addition to an extensive control and monitoring of the seeding process, the control system offers the possibility to adjust the working depth of the front tool, the seed coulters as well as the hydraulic following harrow, while driving on the field.

User-friendliness, cost-effectiveness and an easy to update system are some of the major advantages.

Save passes with BioDrill

By equipping Spirit 600-900C with the mountable small seeder BioDrill, a small seeded crop such as cover crops or ley, can be drilled together with the main crop.

The spreader plates distribute the seed evenly in front of the drill aggregates, where it is covered by the flow of soil around the seed discs and by the press wheel. Alternatively, on the Spirit 600C, a micro granulate fertiliser can be applied together with the seeds in the seed coulter.

An alternative way to use the BioDrill is for slug pellets, which are distributed through nozzles positioned behind the following harrow heavy. Slug pellet and seeder nozzles can be combined.

BioDrill provides an accurate seeding at the same time as saving passes on the field.

QuickStart videos

See our QuickStart movies for your Spirit.

Product concept

Zone 1 - Seedbed preparation

Spirit 600-900C can be adapted to fit differnt farming needs. It is available with different techniques for placing fertiliser with the front tools. The working depth of the front tools can be easily adjusted from the tractor cab.

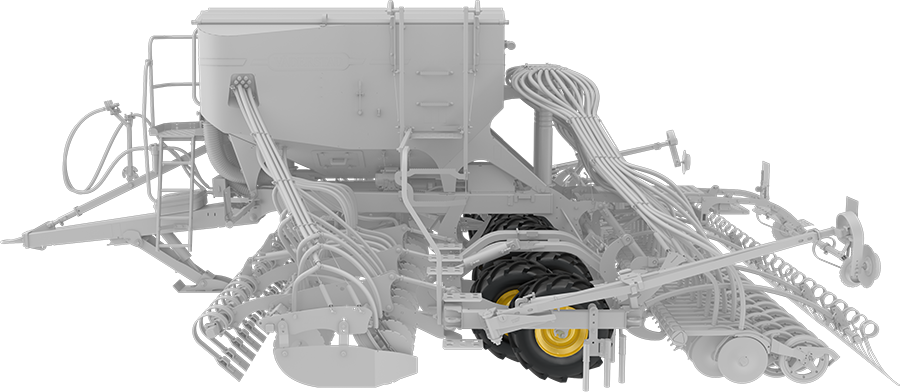

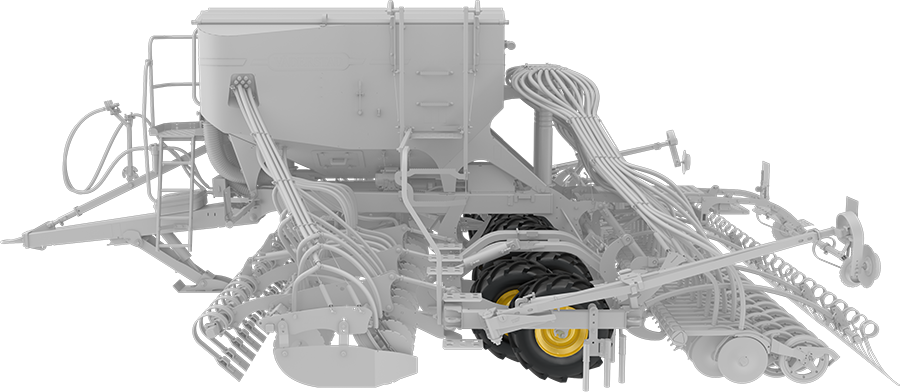

Zone 2 - Consolidation

To ensure a firm seedbed prior to seed placement, large packer wheels consolidates the soil between the front tool and seed coulters. This offers great advantages in lighter soil, as well as in fields where the soil is loose as an effect of a deep cultivation or a cultivation with insufficient reconsolidation.

Zone 3 - Seed placement

Spirit has 380mm large discs for high speed accuracy. The OffSet discs move the soil to the side and place the seed in the bottom of the seed furrow. The soil falls back behind the discs and covers the seed with fine soil. The seed coulter pressure is up to 80kg to ensure a good penetration. The unique TriForce rubber suspension gives a supreme ability to follow ground contour.

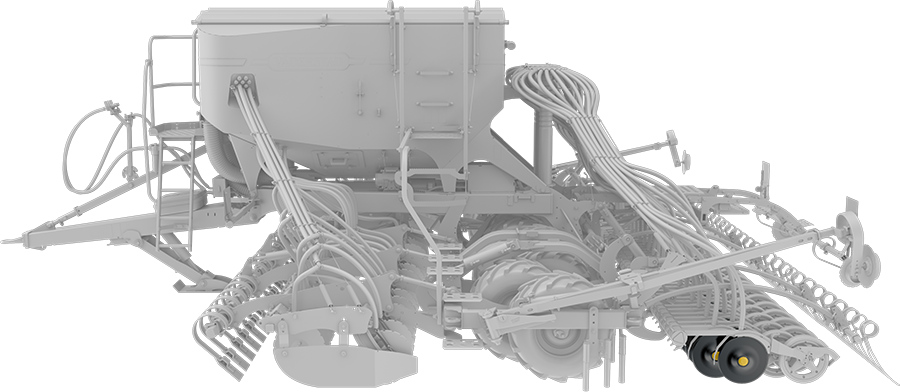

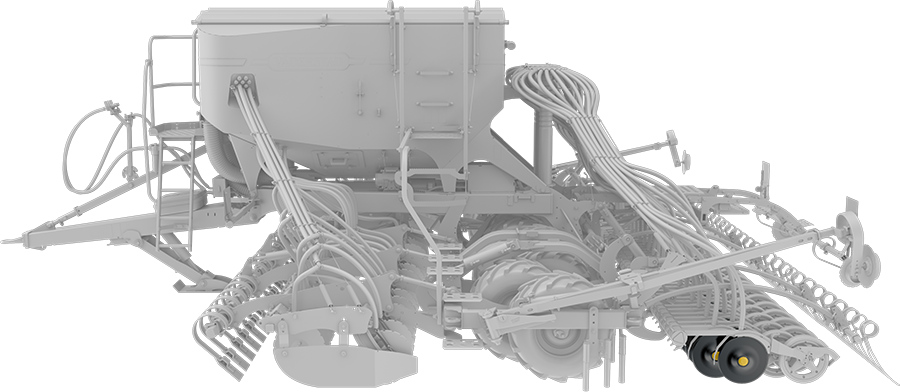

Zone 4 - Reconsolidation

Each individual seed coulter has a wide coulter press wheel. This allows the seed coulters to respond to any irregularities or soil variations on the field, thereby ensuring the working depth is constantly maintained. The generous diameter of the coulter press wheel, further results in a smooth ride with minimal impacts from vibrations, thereby increasing precision at high speed.

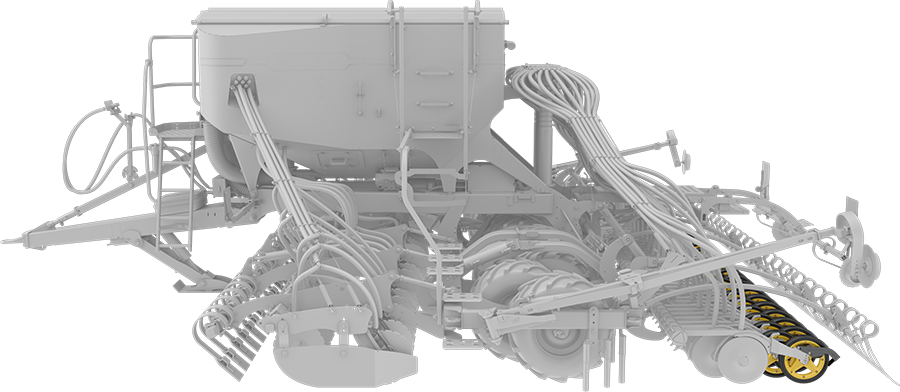

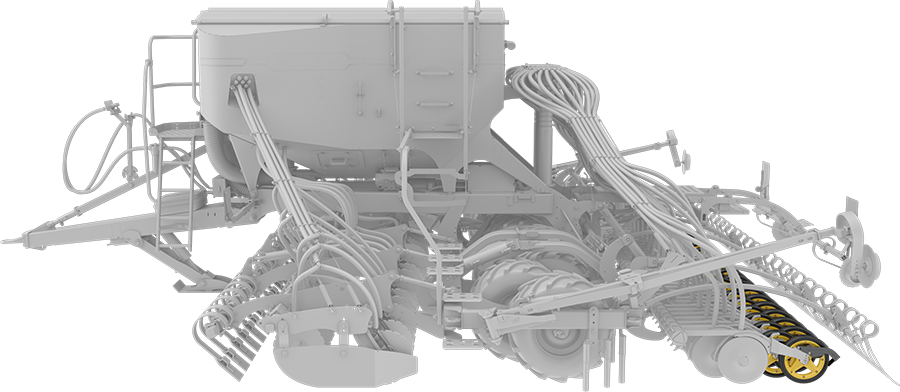

Zone 5 - Finishing

The following harrow is positioned to run in-between the seed rows, so there is no risk of disturbing shallow-drilled seeds.The following harrow creates a loose evaporation barrier to preserve moisture and prevents capping after heavy rain.

Image gallery

Technical data

| Spirit | 600C FIX | 600C Nordic | 600C InLine | 800C FIX | 800C Nordic | 900C FIX | 900C Nordic |

| Metering | Electric | Electric | Electric | Electric | Electric | Electric | Electric |

| Working width (m) | 6,0 | 6,0 | 6,0 | 8,0 | 8,0 | 9,0 | 9,0 |

| Transport width (m) | 3,0 | 3,0 | 3,0 | 3,0 | 3,0 | 3,0 | 3,0 |

| Transport height (m) | 3,56 | 3,56 | 3,56 | 3,85 | 3,85 | 4,0 | 4,0 |

| Transport length (m) | 8,7 | 8,7 | 8,7 | 8,7 | 8,7 | 8,7 | 8,7 |

| Basic weight (kg) | 7600 | 7300 | 7300 | 10160 | 9140 | 10860 | 10900 |

| Volume seed hopper (l) | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 |

| Number of seed coulters | 48 | 48 | 36 | 64 | 64 | 72 | 72 |

| Row spacing seed (mm) | 125 | 125 | 167 | 125 | 125 | 125 | 125 |

| Number of fertiliser coulters | 48 | 24 | 36 | 64 | 32 | 72 | 36 |

| Row spacing fertiliser (mm) | 125 | 250 | 167 | 125 | 250 | 125 | 250 |

| Seed coulter pressure max (kg) | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

| Seed disc diameter (mm) | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Brakes | H/P | H/P | H/P | H/P | H/P | H/P | H/P |

| Recommended working speed (km/h) | 8-14 | 8-14 | 8-14 | 8-14 | 8-14 | 8-14 | 8-14 |

| Wheel dimension (transport wheels) | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 |

| Hydraulic requirement | 4 DA + FR | 4 DA + FR | 4 DA + FR | 4 DA + FR | 4 DA + FR | 4 DA + FR | 4 DA + FR |

| Draught requirement from (hp) | 200 | 170 | 170 | 270 | 220 | 290 | 240 |

| Oil flow requirement (l/min) | 115 | 115 | 110 | 130 | 130 | 130 | 130 |

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| LS = Load sensing | FR = Free return | DA = Double acting | ||

| H = Hydraulic | P = Pneumatic |

* Depending on row spacing - 167/125mm