Seed Hawk 600-900C

6-9 m

250 mm

>175 hp

7000 l

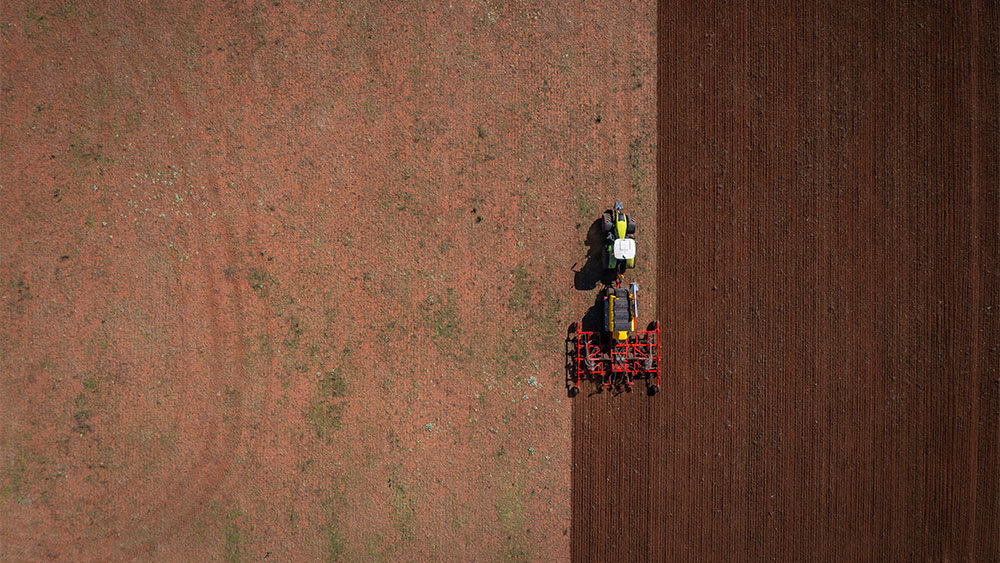

No-till seeding performance

The Seed Hawk 600-900C is a no-till seed drill available in 6, 8, and 9 metre working widths. Its tine coulters create a clean seed slot, placing both seed and fertiliser on undisturbed soil. With a 7,000-litre hopper divided into three compartments, the machine provides the versatility required for modern farming.

Quick and even germination

The double-knife system ensures precise seeding depth and excellent seed-to-soil contact, leading to outstanding emergence.

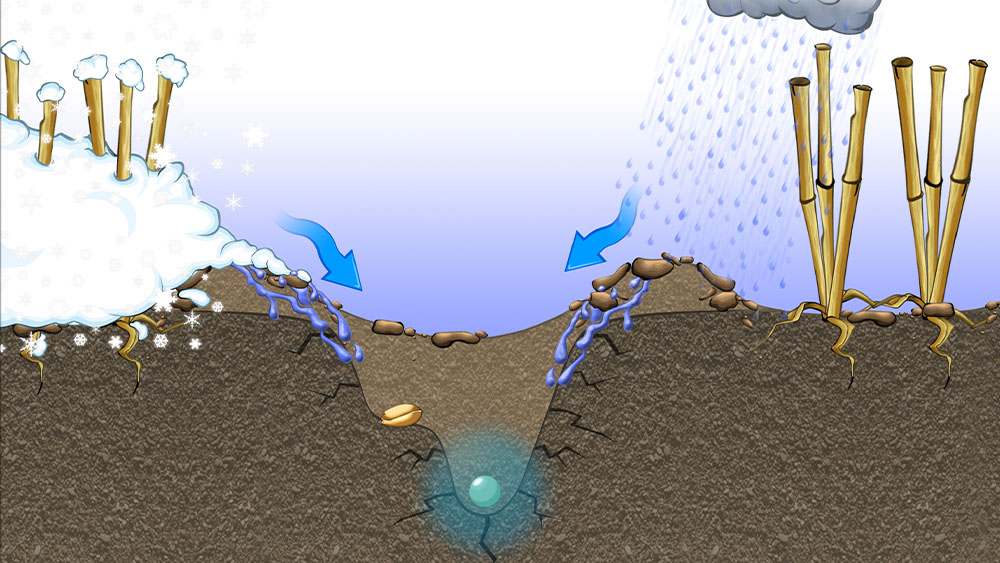

Optimised no-till crop establishment

No compromises are made regarding seed slot hygiene or fertiliser placement, enhancing the chances of success with no-till seeding across varying conditions throughout the crop rotation.

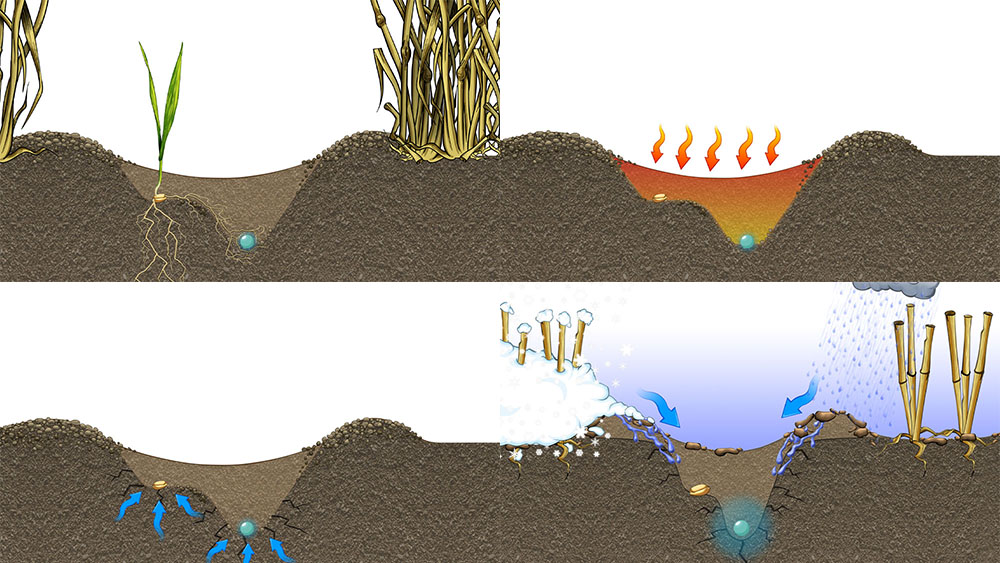

Micro-strip no-till

Seed Hawk employs micro strip-tillage to optimise no-till seeding. This minimises the risk of yield variations, while ensuring the crop is safeguarded from erosion and soil structure damage.

Excellent agronomic performance

Seeding is the operation that sets the foundation for crop performance throughout the year. It is crucial to choose a seeding system that not only produces crops of the highest quality and yield but also performs reliably under all weather conditions. Give your crop the best chance to succeed while reducing risks at the same time.

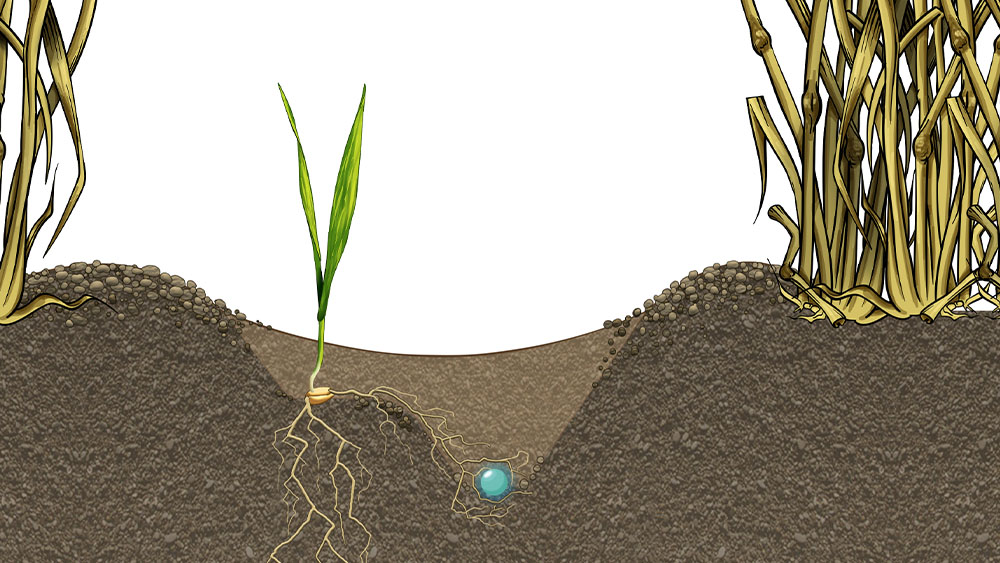

Superior conditions for growth

Germination is the most critical stage of the growth process. It is essential for the plant to access nutrients quickly and safely to gain the early advantage it needs for strong emergence.

Experience the Seed Hawk 600-900C in action

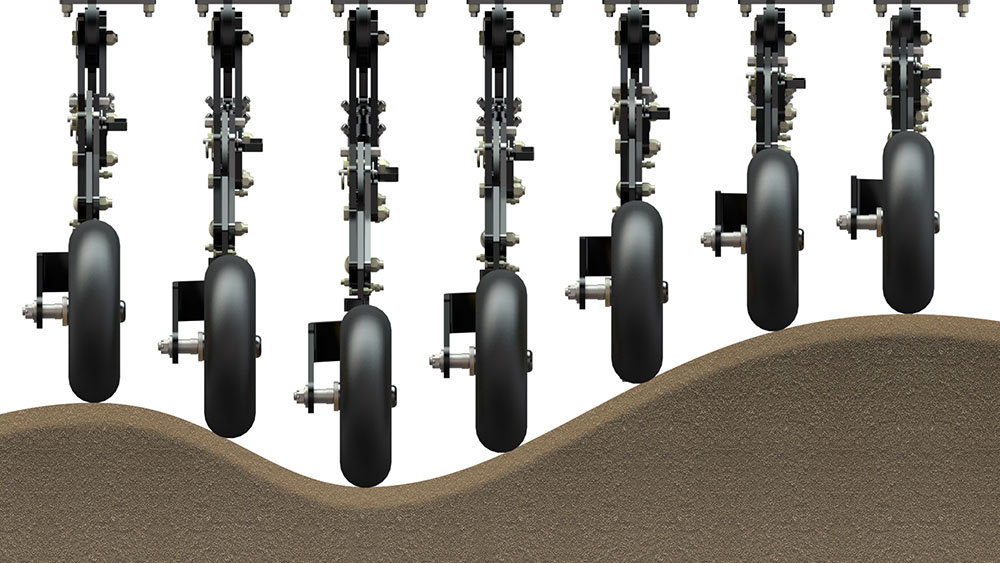

The Seed Hawk coulter

The heart of the Seed Hawk seed drill is its individually mounted tine coulters. Each independent dual-knife tine coulter, along with its packer wheel, ensures unparalleled accuracy in all soil conditions. The result is a excellent quality crop with maximum yield potential.

The front disc extends the boundaries

No-till seed drills have traditionally been a choice between a disc or tine coulter. The tine coulter's main disadvantage has been its inability to cope with heavy residues due to blockages. The front disc on Seed Hawk changes this.

Versatility with large hopper

The Seed Hawk features a 7,000-litre hopper divided into three compartments. Each compartment can be used to place product in either the seed or fertiliser knife. This also allows the mixing of two products in the same airstream. For example, a starter fertiliser, such as phosphorus, can be placed with the seed for quick access, boosting germination and root development.

The optional stainless steel filling auger can fill the hoppers at a capacity of 50 m³/h.

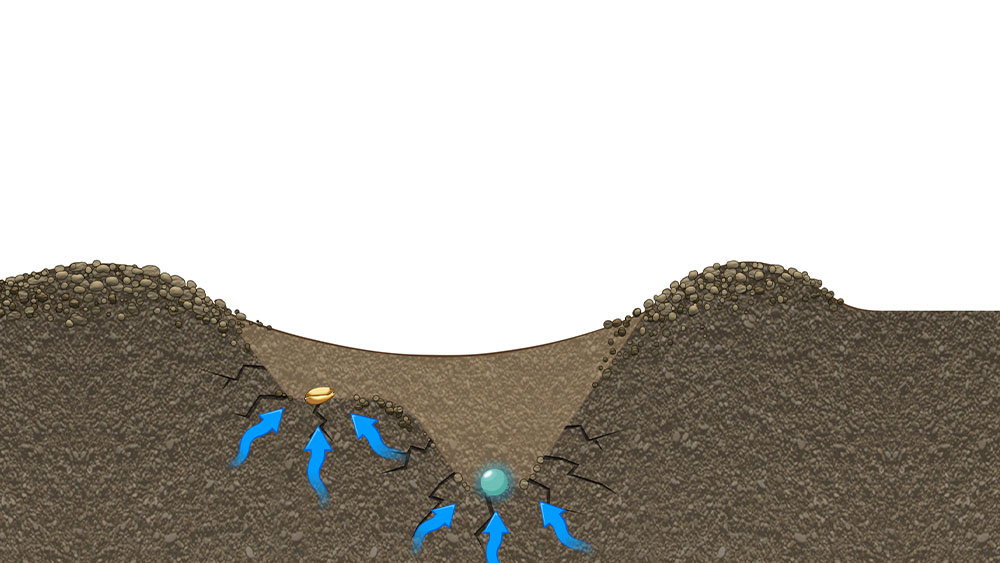

Row-by-row control with extreme adaptability

By controlling each row individually, every seed is provided with optimal conditions for growth. Consistent contour-following ability is crucial in no-till operations where variable field conditions are present, and the Seed Hawk coulter excels in this area.

The tine coulter follows the ground independently by pivoting at the frame. With a contour-following range of +/- 20 cm, each independent opener ensures consistent seed depth, regardless of terrain.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

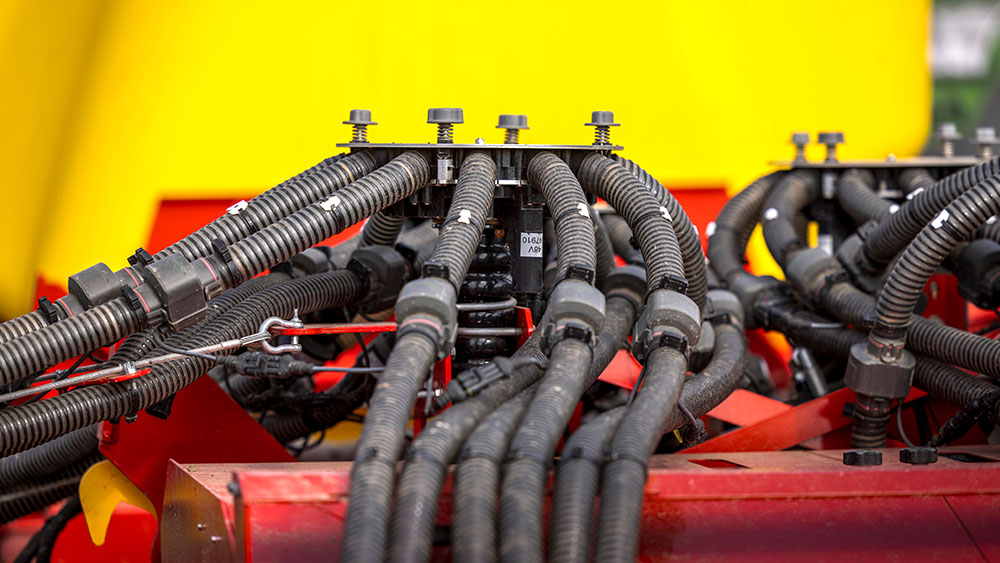

Section control with lifting function

The frame of the 8- and 9-metre versions has three sections, while the 6-metre version has two sections. This allows for sectional shut-off of seed and fertiliser in segments smaller than 3 metres, saving inputs. Additionally, the system enables the lifting of sections to avoid unnecessary ground disturbance at headlands. The system can be operated manually via the iPad or automatically through the ISOBUS Task Controller.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

High capacity output with Fenix III seed meter

The Seed Hawk is equipped with the user-friendly and easily accessible Fenix III metering system. It can handle seed rates as low as 1 kg per hectare, while also enabling high doses, never limiting capacity. One important feature of Fenix III is its soft rotor, which seals the system and reduces air requirements, thereby saving diesel. Fenix III achieves excellent precision, leading to even emergence.

Its precise, reliable, and simple operation allows for a high degree of flexibility, accommodating a wide range of seed and fertiliser applications.

E-Control – The new generation control system

The iPad-based Väderstad E-Control system wirelessly connects to the Väderstad machine, enabling full access to its functions and data. You benefit from user-friendly remote setup and calibration, as well as real-time monitoring and control. E-Control is a fully portable control system, ready to be used whenever and wherever required. When calibrating the Väderstad machine, you can take the portable iPad out of the tractor and control the calibration from outside.

Blockage monitoring with SeedEye

The optional Väderstad SeedEye system monitors for blockages, instantly alerting you to any disruptions in seed or fertiliser flow. This ensures optimal field efficiency and control, making SeedEye the ultimate tool for modern farming.

CrossCutter Disc: The perfect companion for no-till seeding

No-tillage seeding has traditionally involved a zero-tolerance approach to tillage, primarily to protect soil structure and fauna. However, this approach has sometimes resulted in high costs due to pests, performance problems, and unstable yields. Although the Seed Hawk 600-900C performs exceptionally well in no-tillage seeding on its own, pairing it with the CrossCutter Disc further reduces the risks associated with no-till farming. The ultra-shallow tillage delivered by the Carrier disc cultivator, fitted with the CrossCutter Disc, provides new possibilities.

A machine walkaround with Seed Hawk 600-900C

Product concept

Zone 1 – Cutting (optional)

To ensure field performance when seeding directly in heavy crop residues or after cover crops, the Seed Hawk knife coulter can be complemented with a front disc as an option.

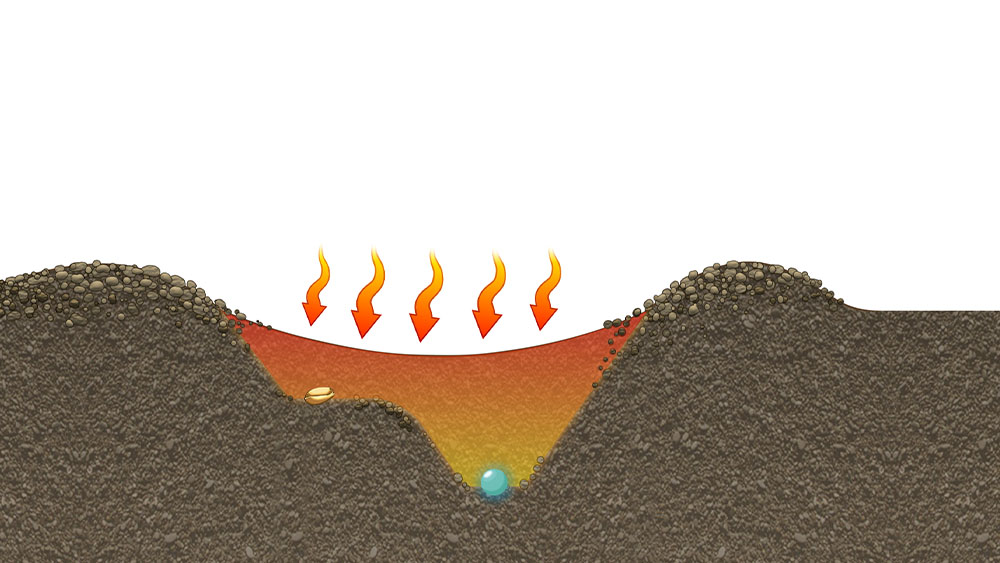

Zone 2 – Fertiliser placement

The fertiliser knife has a strong forward angle and functions similarly to a cultivator point, though without the mixing capability. It lifts moist soil and pushes larger clods to the side, leaving fine tilth in the seed slot. Its soil-penetrating ability ensures maximum depth with minimal weight requirements, thus saving diesel.

Zone 3 – Seeding

The seed knife, with its backward angle, carves a shelf from the sidewall and dresses it with fine tilth to promote seed-to-soil contact and rapid germination. The Seed Hawk dual-knife coulter ensures exceptionally high germination rates, allowing for low seed rates.

Zone 4 – Reconsolidation

The Seed Hawk press wheel applies more pressure on the fertiliser row to seal in moisture and aid dissolution. By applying slight sideways pressure over the seed, the press wheel prevents capping, ensuring perfect contact between seed and soil. The packer wheel is positioned behind the two knives, ensuring it always runs in tilled soil. This prevents minor surface variations from affecting the seed depth where it is neither intended nor needed. Consequently, the tine coulter operates smoothly and delivers excellent depth precision.

Gallery

Technical data

| Seed Hawk 600C | Seed Hawk 800C | Seed Hawk 900C | |

| Working width (m) | 6.0 | 8.0 | 9.0 |

| Transport width (m) | 3.0 | 3.0 | 3.0 |

| Transport height (m) | 2.9 (with auger 3.5) | 3.9 | 4.2 |

| Transport length (m) | 11.8 | 11.8 | 11.8 |

| Basic weight (without discs and empty hopper) (kg) | 8900 | 10900 | 11300 |

| Max axle load front/rear (kg) | 3500/7200 | 3800/7700 | 3900/9600 |

| Hopper capacity (l) | 7000 | 7000 | 7000 |

| Filling height (m) | 3.0 | 3.0 | 3.0 |

| Number of seed/fertiliser coulters | 24/24 | 32/32 | 36/36 |

| Row spacing, seed (mm) | 250 | 250 | 250 |

| Coulter pressure (kg) | 50-150 | 50-150 | 50-150 |

| Hydraulic requirements without filling auger | 2DA, FR+D+P+LS | 2DA, FR+D+P+LS | 2DA, FR+D+P+LS |

| Oil flow requirement (l/min) | 85 | 110 | 110 |

| Draught requirement (hp) | 175-225 | 225-275 | 225-300 |

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| CD = Case drain FR= Free return |

LS = Load sensing P = Power beyond |

DA = Double acting |

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.