Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Engineered for professionals

Some see just a piece of steel. We see the possibility for outstanding emergence and the best overall economy. Professional farmers know that the most important parts of the machine are those that run through the soil, doing the really tough work. These parts have to be durable, fit perfectly and have excellent agronomic properties. That’s why we make wear parts for professionals.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Lowest cost per hectare

We always aim for the smartest solutions, the highest quality and the best overall economy. That’s why we address professional farmers. Farmers who plan the purchase of wear parts in the same way as the whole annual business. There is much in farming that can’t be predicted. Like the seasons and the weather. But with good planning and the right equipment, you can get the most out of each year. And our goal is always to bring you the lowest cost per hectare.

Optimized Performance

The new digital magazine for all Väderstad farmers. Valuable information, news, wear parts, accessories, and maintenance tips.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Quality is in the details

Quality is the result of thinking of both the simple and the complex details. A well-known fact for all professional farmers. Manufacturing high quality wear parts for premium machines is an agreement between us and the farmers, and one of our greatest passions. Watch our new movie ‘Quality is in the details’ to see how we do it.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Follow the Genuine Parts from the drawing board to the field in the movie “Not just a piece of steel”.

Voices of Genuine farmers

Meet the professional farmers who know that it takes Genuine Parts to reach full agronomic potential and create the best economy.

Revolutionary innovations

Väderstad is known for pushing the limits, continuously presenting ground-breaking innovations based on new thinking. The greatest potential to improve the final emergence is found in the soil, where it actually happens. That’s why many of Väderstad’s most revolutionary innovations are wear parts.

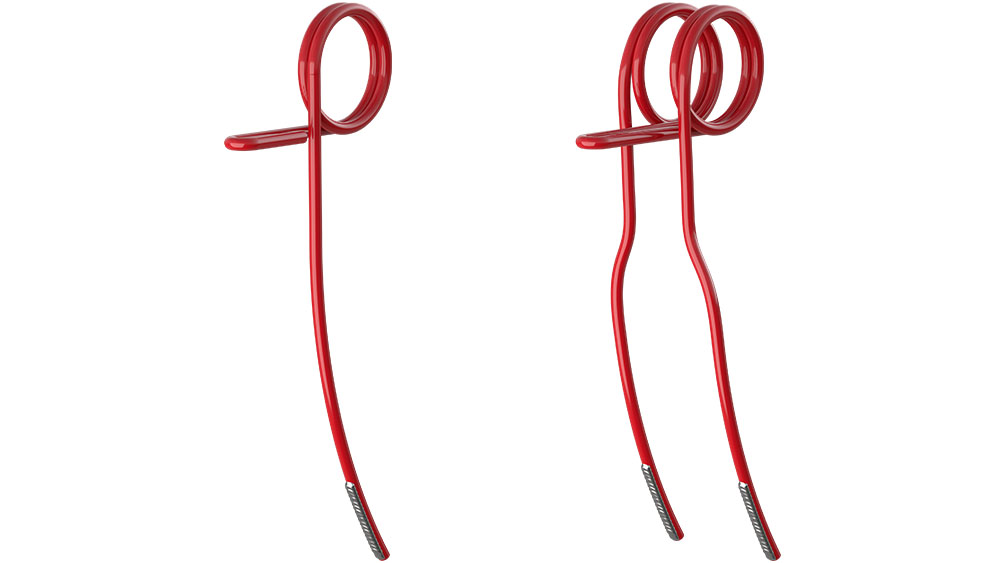

The long-life Following harrow Marathon

Comparing the new Following harrow Marathon to the standard Following harrow, demonstrates a prolonged lifetime in the field. Since the length of the tine remains constant it maintains its same vibrating, and therefore, soil sorting capabilities. The initial set angle also stays the same. This means a perfect working result year after year, spares the farmer time in the workshop and maximises value adding time.

CrossCutter disc

Works ultra-shallow and intensively at high speed, creating the perfect seedbed for the residues to decompose and the seedbank to germinate. The CrossCutter Disc is an outstanding performer in oilseed rape stubble, cover crops, grain stubble and on ploughed land. The shallow working depth of 2-3 cm leads to lower fuel consumption and a working speed of up to 20 km/h.

Marathon Edge point

The shape of the new Marathon Edge increases the soil searching ability while reducing the draw force in heavy soils. Marathon Edge is also a perfect fit to the MixIn shin, which increases the mixing ability in field. Combined with the awarded durability of the Marathon point family, the Marathon Edge is a smart point of choice for the Väderstad Swift cultivator - ensuring a longer working life than a standard point and longer durations between changing points.

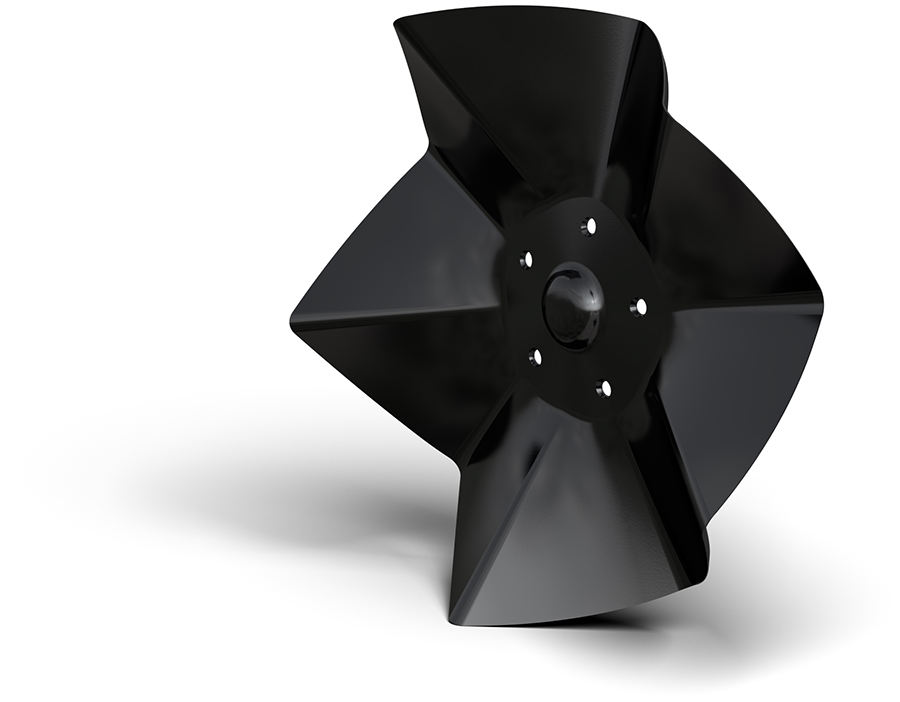

BreakMix point

Combines the advantages of breaking compactions with highly intensive mixing. The lower part breaks compactions at depth, brings soil up to the surface and creates water transport both up and down. The upper shovels throw the soil up for mixing and create a perfect seedbed for fast decomposing. BreakMix lowers the input cost and improves the agronomical results.

MixIn shin

All Väderstad tine cultivators are equipped with the unique MixIn shin. The shin throws the material forwards instead of upwards, which forces the material to pass the tine twice. This doubles the mixing and crumbling effect throughout the working depth and provides the same conditions over the entire field. The MixIn shin improves the result, increases the yields and saves diesel.

Marathon points

Väderstad’s hard metal point revolutionized the wear part market when it increased the working life up to 10 times, compared with a standard point. Marathon points keep the exact working depth through their whole lifetime. They guarantee a perfect working result year after year, spare you time in the workshop and enable you to work in the field when the weather is at its optimum.

Point and disc configurator

Väderstad provides points and discs for all needs and conditions. To optimize the working result, it’s important to use the right wear part. Väderstad’s point and disc configurator helps you find the right parts for your machine and conditions.

Väderstad through and through

Väderstad parts are designed, tested and produced at Väderstad Components in Sweden. As a manufacturer of premium machines for professionals, it’s our duty to provide original parts of the highest quality, with a perfect fit. Even though we already produce the best parts for Väderstad machines, we keep innovating, testing and improving wear parts in our ultra-modern technology lab. For us, there is no such thing as “good enough”.

V-55 steel

V stands for Väderstad and 55 for the hardness. Our Swedish quality hardened steel for discs has the perfect combination of high hardness and elasticity. This means that the discs perform with extreme durability and excellent resistance to external forces in the field. All for outstanding emergence and a long working life in harsh conditions.

Lifetime warranty

Väderstad’s genuine discs are manufactured in high quality V-55 Swedish steel at Väderstad Components. The production reflects the same top-of-the-line product philosophy as all Väderstad products, which altogether guarantees the best value available on the market. This is why Väderstad provides a lifetime warranty on all discs.