Wil-Rich 2500 Series

4 - 18.3 m

25.4 cm

>100 hp

30.5/38.1 cm

Superior tillage performance in tough soil conditions

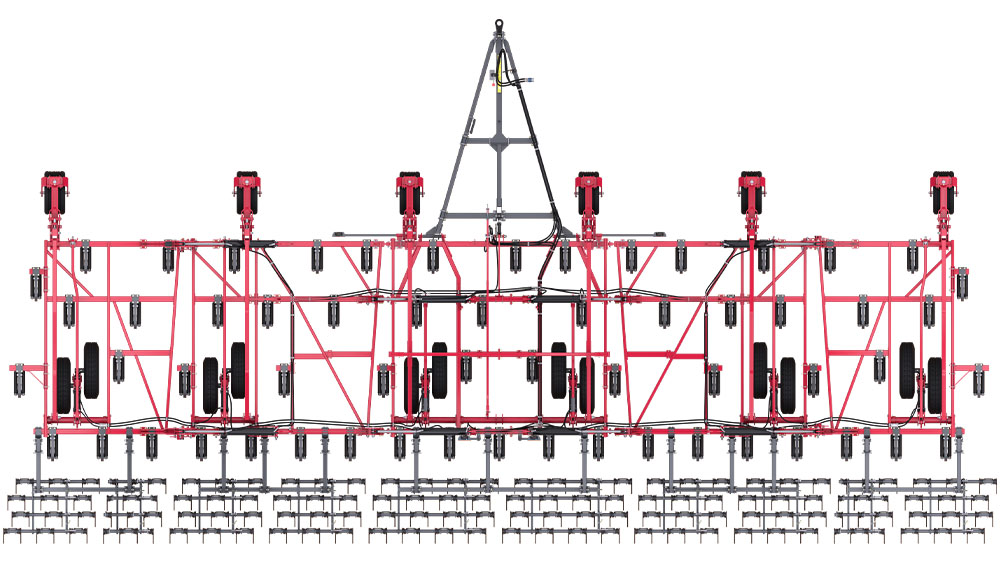

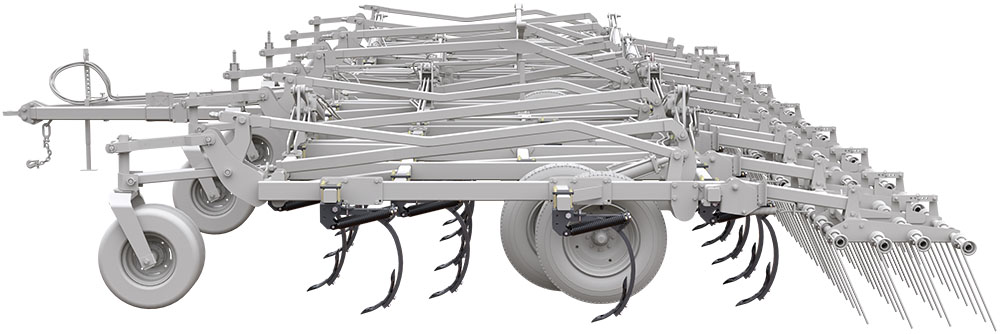

The Wil-Rich 2500 Series Chisel Plow is an excellent fall tillage tool for mixing soil and breaking up shallow compaction layers. The deep frame utilises four ranks to improve the flow of heavy residue from today’s higher-yielding crops. It has an extremely heavy-duty design that maintains tillage depth, even in the toughest soil conditions. It is one of the strongest tillage implements on the market.

Optimal soil mixing

The tines on the Wil-Rich 2500 Series are designed to turn over and mix the soil. They produce an optimal level of tilth for many conventional tillage operations.

Post-harvest weed management

The Wil-Rich 2500 Series is an excellent option for mechanical weed control, as the soil mixing action of the tines can effectively uproot tough weeds.

Shallow compaction reduction

The 25.4 cm working depth of the Wil-Rich 2500 Series can break up shallow compaction layers, helping to promote water infiltration and root growth.

Excellent agronomic performance

A post-harvest tillage pass is essential for creating an improved seedbed in the spring, laying the groundwork for operational success throughout the year. Ensure your crop has the best opportunity to thrive while simultaneously minimising risks.

Built for tough tillage: Versatility and strength combined

The Wil-Rich 2500 Series Chisel Plow offers adjustable tine spacing, available in 30.5 cm (12 in) or 38.1 cm (15 in), and trip pressure options of 295 kg (650 lbs) or 454 kg (1,000 lbs), giving you the flexibility to adapt to your soil conditions. Its reinforced 9mm steel frame ensures durability in even the toughest environments, while the compact transport design allows for easy manoeuvring and storage. Additionally, you can choose between a level lift or floating hitch, providing precise control based on your field's unique terrain, ensuring optimal tillage performance in any condition.

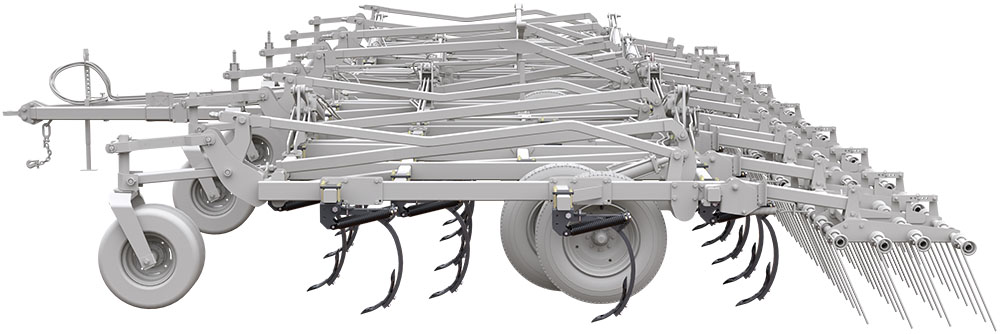

Level lift hitch for consistent levelling

The level lift hitch is designed to keep the unit level during both field operation and transport. The operator can adjust the working depth while maintaining consistent depth from the front to the rear of the unit.

The level lift hitch is available on all Wil-Rich 2500 models.

Floating hitch for contour following

The floating hitch pivots between the tractor and the main frame, allowing the unit to follow the contour of the ground. The front caster gauge wheels are mechanically synchronised with the rear axle, enabling the unit to maintain a consistent working depth from front to rear.

The floating hitch is available on Wil-Rich 2500 Series models 9.4 m (31 ft) and larger.

Deep frame with excellent trash flow for minimal plugging

The Wil-Rich 2500 Series has four ranks of tines with a deep frame design. This allows for generous spacing between tines so that soil and heavy residue can flow freely through the unit without plugging. The chisel plough is available with 30.5 or 38.1 cm adjustable tine spacing to accommodate different field conditions.

Tines built for heavy soils

Heavy-duty trip assemblies on the Wil-Rich 2500 Series help penetrate and maintain depth in tough, heavy soils. Wil-Rich’s legendary on-edge tines have zero-maintenance pivots, which are built for the machine’s lifetime to provide excellent reliability with minimal downtime.

Compression spring trip assembly

453 kg compression trip spring assemblies allow the chisel plough to work in heavy, compacted soils. Tine dimensions are 3.2 x 5.1 x 76.2 cm, and they’re engineered with a 50-degree approach angle to ensure deep penetration and thorough soil mixing.

Extension spring trip assembly

295 kg extension spring trip assemblies are designed for optimal penetration and effective soil engagement. Tine dimensions are 5.1 x 3.2 x 81.3 cm, with a 54-degree approach angle for reliable performance.

A closer look at the Wil-Rich 2500 Series

Compact transport design

The Wil-Rich 2500 Series center folding wings allow a compact transport design making it easy to move between fields. Its over-center folding wings allow for a narrow transport width, minimising the space required for transport.

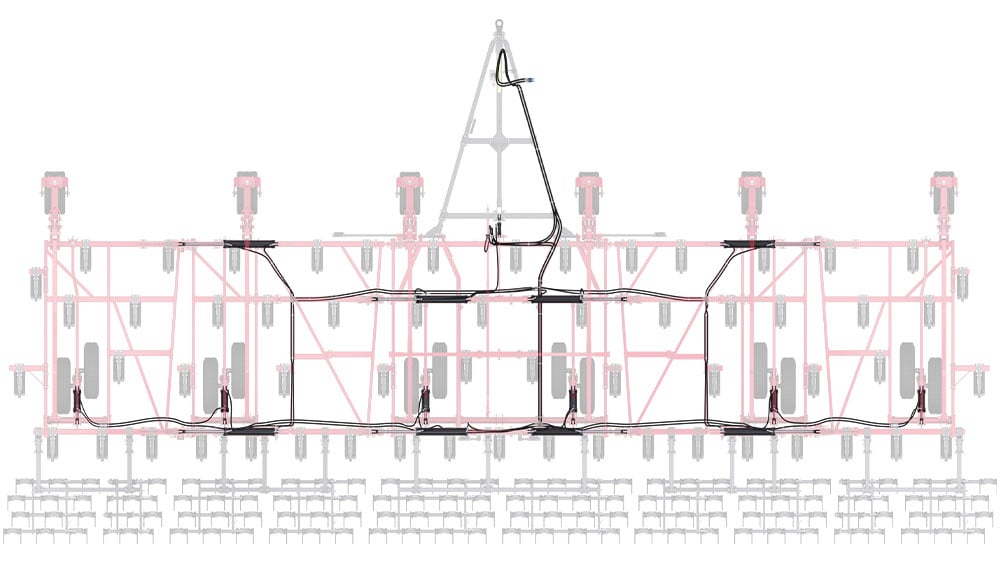

Hydraulics & depth control

The Wil-Rich 2500 Series is equipped with a 25.4 cm (10 in) stroke Prince wing fold cylinder, designed to vary the bore size for lift circuit phasing. For added convenience, the chisel plough features a single-point depth control, allowing you to easily adjust the working depth for the entire implement from one location. This eliminates the need for manual adjustments at each gauge wheel, saving you both time and effort during operation.

Gauge wheels for precise control and stability

Hydraulic castering gauge wheels come standard on floating hitch models, providing precise control and stability. On models with wings measuring 9.45 m (31 ft) and larger, ratchet-adjust castering gauge wheels are standard, offering easy adjustment and reliable performance.

Reliable transportation

The Wil-Rich 2500 Series is equipped with 12R22.5 x 8.25 tyres on 8-bolt hubs, used on all in-frame walking tandems. This setup enhances reliability during transport and provides better performance in wet working conditions, ensuring smooth and dependable movement between fields.

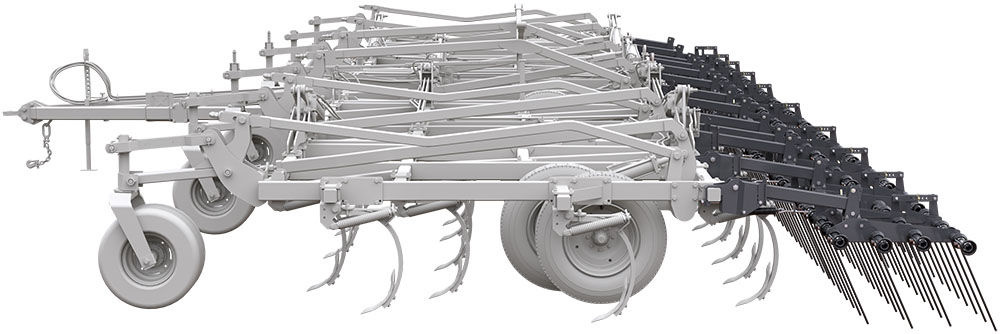

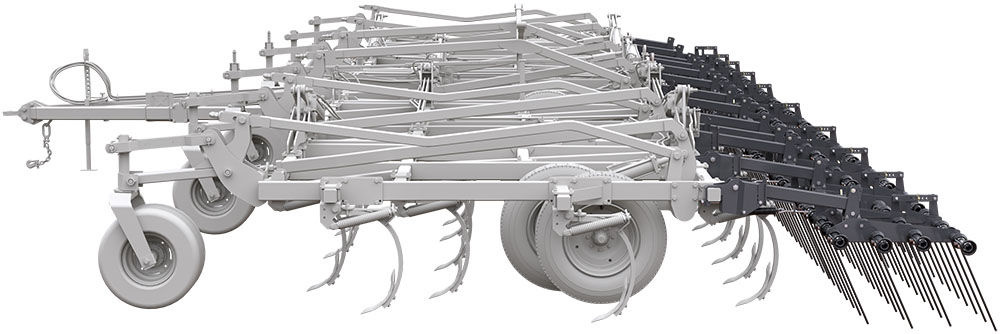

Finishing attachments level the soil

The Wil-Rich 2500 Series can be equipped with two finishing attachment options to achieve a smooth, level field finish. The 3- or 4-bar harrow includes five settings for tooth angle adjustment, allowing users to tailor the harrow’s aggressiveness to match ground conditions and the amount of surface residue.

Product concept

Zone 1 – Mixing

The tines on the Wil-Rich 2500 are ideal for mixing soil while breaking up shallow compaction layers. Their heavy-duty design ensures optimal performance in various conditions, from lighter ground to heavy, compacted soils. Two spring trip assembly options are available to suit the needs of different operations.

Zone 2 – Levelling

Finishing attachments level the soil. The Wil-Rich 2500 series can be equipped with the 3- or 4-bar coil tine harrow, featuring five adjustments for tooth angle. These adjustments allow the user to set the harrow’s aggressiveness according to ground conditions and the amount of residue on the soil surface.

Technical data

| 2510 CPR 13 | 2510 CPR 13-15 | 2510 CPR 13-17 | |

| Rigid/Folding | rigid | rigid | rigid |

| Hitch type | level lift | level lift | level lift |

| Number of tines 12 in/15 in | 13/10 | 15/12 | 17/14 |

| Working width for 12 in/15 in (m) | 4/3.8 | 4.6/4.6 | 5.2/5.3 |

| Inner wing (m) | - | - | - |

| Outer wing (m) | - | - | - |

| Transport width (m) | 4.1 | 4.5 | 5.2 |

| Transport height (m) | 2.1 | 2.1 | 2.1 |

| Weight* (kg) | 2513 | 2639 | 2813 |

| Draught requirement (hp) | 100-156 | 120-180 | 140-204 |

| 2530 CPW 19 | 2530 CPW 19-21 | 2530 CPW 19-23 | |

| Rigid/Folding | folding | folding | folding |

| Hitch type | level lift | level lift | level lift |

| Number of tines 12 in/15 in | 19/- | 21/16 | 23/18 |

| Working width for 12 in/15 in (m) | 5.8/- | 6.4/6.1 | 7/6.9 |

| Inner wing (m) | 0.9 | 0.9 | 0.9 |

| Outer wing (m) | - | - | - |

| Transport width (m) | 4.3 | 4.3 | 4.3 |

| Transport height (m) | 3 | 3 | 3.1 |

| Weight* (kg) | 3353 | 3480 | 3654 |

| Draught requirement (hp) | 190-228 | 160-252 | 180-276 |

| 2530 CPW 25 | 2530 CPW 25-27 | 2530 CPW 25-29 | |

| Rigid/Folding | folding | folding | folding |

| Hitch type | level lift | level lift | level lift |

| Number of tines 12 in/15 in | 25/20 | 27/22 | 29/24 |

| Working width for 12 in/15 in (m) | 7.6/7.6 | 8.2/8.4 | 8.8/9.1 |

| Inner wing (m) | 1.8 | 1.8 | 1.8 |

| Outer wing (m) | - | - | - |

| Transport width (m) | 4.3 | 4.3 | 4.3 |

| Transport height (m) | 3.4 | 3.5 | 3.6 |

| Weight* (kg) | 4450 | 4576 | 4750 |

| Draught requirement (hp) | 200-300 | 220-324 | 240-348 |

| 2530 CPW 31 | 2530 CPW 31-33 | 2530 CPW 31-35 | |

| Rigid/Folding | folding | folding | folding |

| Hitch type | level lift or floating | level lift or floating | level lift or floating |

| Number of tines 12 in/15 in | 31/24 | 33/26 | 35/28 |

| Working width for 12 in/15 in (m) | 9.4/9.1 | 10/10 | 11/11 |

| Inner wing (m) | 2.7 | 2.7 | 2.7 |

| Outer wing (m) | - | - | - |

| Transport width (m) | 5.8 | 5.8 | 5.8 |

| Transport height (m) | 3.8 | 4.1 | 4.4 |

| Weight with level lift hitch* (kg) | 6945 | 7071 | 7245 |

| Weight with floating hitch* (kg) | 7713 | 7839 | 8013 |

| Draught requirement (hp) | 240-372 | 260-396 | 280-420 |

| 2530 CPW 31-37 | 2530 CPW 31-39 | 2530 CPW 31-41 | |

| Rigid/Folding | folding | folding | folding |

| Hitch type | level lift or floating | level lift or floating | level lift or floating |

| Number of tines 12 in/15 in | 37/30 | 39/32 | 41/34 |

| Working width for 12 in/15 in (m) | 11.3/11.4 | 11.9/12.2 | 12.5/13 |

| Inner wing (m) | 2.7 | 2.7 | 2.7 |

| Outer wing (m) | 0.9 | 0.9 | 0.9 |

| Transport width (m) | 5.8 | 5.8 | 5.8 |

| Transport height (m) | 3.8 | 3.8 | 3.8 |

| Weight with level lift hitch* (kg) | 7824 | 7950 | 8124 |

| Weight with floating hitch* (kg) | 8592 | 8718 | 8892 |

| Draught requirement (hp) | 300-444 | 320-468 | 340-492 |

*Approx weight: base wt + 12 in tine spring (number of springs x 650 lbs extension springs).

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| LS = Load sensing | FR = Free return | DA = Double acting | ||

| H = Hydraulic | P = Pneumatic |

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.